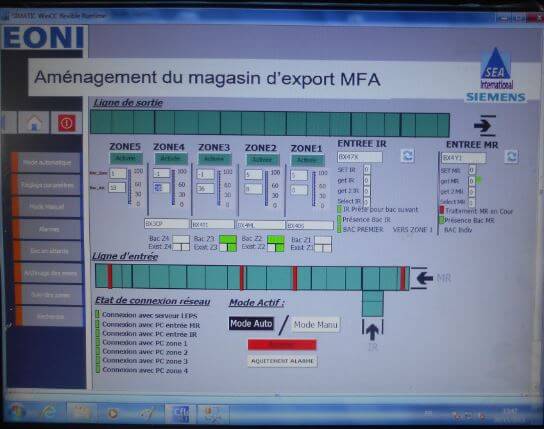

Adjusting of export store MFA

the project is to improve storage management of a manually operated store with pallet to semi-automated warehouse

the store is managed with two conveyor line, a row of bins and a second store for the output bins.![]()

This management system Warehouse including fixed barcode scanners and sensors for presence bins, holders, for each zone or treat each controlled by PLC or manually.

the project is based on works, supply, fabrication, paint, transport and installation:

- Two lines 51m conveyor which ensures the displacement of the trays 50 Kg

- 22 tray stop system

- 6 Barcode readers

- Electrical cabinet Automation and Control Command System.

- Modification of five mini-lift trucks.

This project includes an automative parts:

- Programmable SIEMENS SIMATIC S7 300 CPU 151-8 PN / DP and Profibus profinet Communicating with a PC of supervision that will be connected to the network ETHERNET From the factory, with 64 digital input / digital output 64 only.

A Mechanical parts:

- Lines conveyors length 51m rolls

- Retainers bins

An Electrical parts:

- Control cabinet with equipment

- Fixed laser scanners

- Infrared sensors

- Manual control box

Warehouse LEONI

Mini-lift trucks

Conveyor